Type:

Process

IPR Status:

Copyright

Secured In:

India

Application/uses:

Austempered Ductile Iron (ADI) can be used for manufacturing of wide range of components for the following engineering sectors

- Automobile Sector

- Mining machinery

- Agricultural machinery and implements

- Construction equipment

Salient Technical Competing Features:

Advanced manufacturing methods which produce the components closer to its final geometry in minimum number of stages is known as Near Net Shape (NNS) manufacturing. NNS technologies are now getting wider acceptance all over the world for obvious benefits like maximum utilization of raw material, minimum energy requirement and competitive price of the final product. One of the NNS technologies is - Manufacturing of Engineering Components through ADI route. ADI components are now being used in different types of engineering machinery because it offers a combination of design flexibility, higher strength-to-weight ratio, good toughness, superior wear resistance and low cost of production. Design innovation and development of new process technology for manufacturing of ADI components will benefit simultaneously the manufacturing industries and user segments.

ADI is a new class of engineering material which is being manufactured from SG Iron through Austempering process. Austempering is an isothermal heat treatment process applied to ferrous materials to produce a microstructure that is stronger and tougher than the structures resulting typically from conventional heat treatment. Mechanical properties of ADI product depends mainly on composition and heat treatment parameters. ADI manufacturing technology consist of Computerised methoding-Pattern making- Selection of raw material – Melting and Casting of SG iron component – Machining of component - Austempering treatment – Finishing operation- Inspection. By controlling the process parameters and composition it is also possible to produce high quality SG iron castings which is essential for manufacturing ADI products. Based on the mechanical properties, ADI material are classified into 6 different grades(as per ASTM 897-06). Each grade can be produced through closer control of composition, casting parameters and heat treatment parameters.

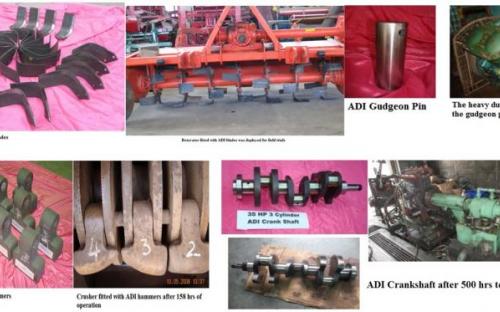

CSIR- CMERI has successfully developed the comprehensive process technology for manufacturing of ADI components like L type Rotavator blades for agricultural sector, Crank shaft for 35 hp tractor engine, Hammers for mining sector and Gudgeon pin for heavy duty compressor. Field trials of these components revealed encouraging results.

Advantages of ADI technology –

- Easy to produce complex geometry components

- Mechanical properties comparable to some grades of steel

- 20% Cheaper than forged steel parts

- Needs less energy than forged steel parts

- Superior wear / abrasion resistance

- 10% lighter than steel

Environmental Consideration:

Electrically operated furnaces are acceptable to our industries for regular production of large volume of engineering components through casting and heat treatment route. Total energy requirement for ADI process route is much less compared to the total energy required to produce steel parts. ADI process technology environment friendly. More over the ADI parts can be easily recycled by local MSME.

Status of Commercialization:

Technology has been transferred to one Indian Industry in non-exclusive basis.

Major Raw Materials To Be Utilized :

Steel scrap, High quality Pig iron, foundry returns, ferroalloy and foundry chemicals like sodium silicate, CO2 gas and silica sand, refractory paints. Heat treatment salt

Major Equipments:

Induction melting Furnace, Converter/ladle for Mg treatment of liquid iron, Heat treatment furnace, Fettling equipment, Lathe and Milling machine

Techno Economic:

Available on enquiry basis. ADI components are 20-30% less costly than steel counter parts

Technology Package:

Technology package for above ADI components can be handed over to the industries as and when required. The ADI process technology developed at CSIR –CMERI, can also be extended for manufacturing of other complex geometry engineering components.

Content Details:

For commercial purpose,

Head, BDG

CSIR-Central Mechanical Engineering Research Institute,

Mahatma Gandhi Avenue

Durgapur-713209, West Bengal

Tel: (M) 9434778128, Fax: +91-343-2548204

E-mail: bdg [at] cmeri [dot] res [dot] in

Level/Scale of Development:

Production ready

Collaborating for a stronger future

Collaborating for a stronger future  CSIR-CMERI Hosts Curtain Raiser for 11th India International Science Festival (IISF) 2025

CSIR-CMERI Hosts Curtain Raiser for 11th India International Science Festival (IISF) 2025  Director CSIR-CMERI Inaugurates Indigenous Surgical Artery Forceps Manufacturing Setup

Director CSIR-CMERI Inaugurates Indigenous Surgical Artery Forceps Manufacturing Setup  Municipal Solid Waste Segregation Pilot Plant (Click banner to read more)

Municipal Solid Waste Segregation Pilot Plant (Click banner to read more)  Commercializing the CSIR PRIMA ET-11 Electric Tractor

Commercializing the CSIR PRIMA ET-11 Electric Tractor